500kg / Batch Post Hopper Lifter Industrial Lifting Equipment

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | XIANDAO |

| Certification: | CE / UL / SGS / EAC / CR – TU |

| Model Number: | LDT |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 SET |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden case |

| Delivery Time: | 8~18 WEEKS |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 SETS PER MONTH |

|

Detail Information |

|||

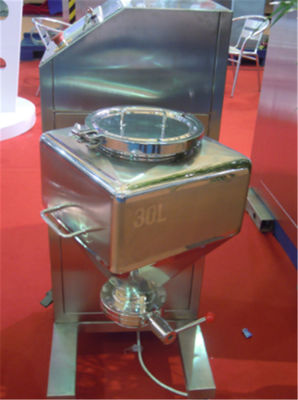

| Product Name: | LDT Series Post Hopper Lifter | Metal Material: | SUS316/SUS304/ CARBON STEEL ,ETC |

|---|---|---|---|

| Capacity: | 20-500kg/batch | Volume: | 20-2000L |

| Motor: | ABB/ SIEMENS /SEW | Principle: | The Mixing Body (material Vessel) |

| Document: | FAT/ IQ / OQ / PQ | Certification: | CE / UL / SGS / EAC / CR – TU |

| Highlight: | 500kg Industrial Lifting Equipment,2000L Industrial Lifting Equipment,500kg material lifting equipment |

||

Product Description

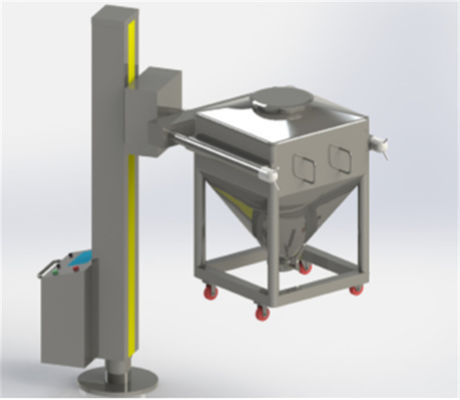

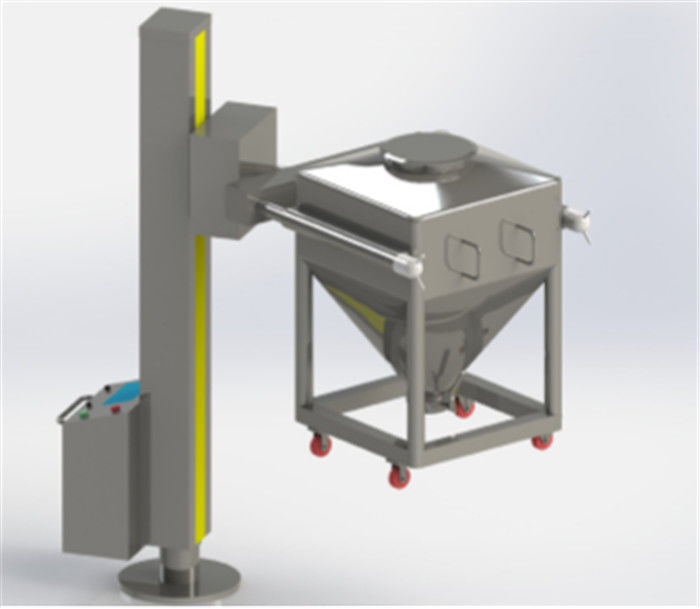

LDT Series Post Hopper lifter

Product details

Hydraulic Control Hopper Lifter Machine For Pharm Industry Bulk Drug Intermediates

| Metal Material: | SUS316/SUS304/ CARBON STEEL ,ETC | Volume: | 20-2000L |

| Motor: | ABB/ SIEMENS /SEW | Document: | FAT/ IQ / OQ / PQ |

| Principle: | The Mixing Body (material Vessel) | Capacity: | 20-500kg/batch |

Technical parameters

|

Type |

Size of the structure (mm) | Net load (kg) | Total power (kW) | ||||||||

| H | H1 | H2 | H3 | W | W1 | R | L1 | L2 | |||

| LDT200 | >3500 | 2500 | 3500 | 3350 | 600 | 700 | 1600 | 550 | 800 | 160 | 1.5 |

| LDT400 | >3800 | 2500 | 3800 | 3630 | 800 | 700 | 1800 | 550 | 1000 | 320 | 1.5 |

| LDT600 | >3800 | 2500 | 3800 | 3690 | 1000 | 700 | 2000 | 550 | 1100 | 480 | 2.2 |

| LDT800 | >4000 | 2500 | 4000 | 3890 | 1000 | 750 | 2000 | 600 | 1100 | 640 | 2.2 |

| LDT1000 | >4200 | 2500 | 4000 | 3990 | 1200 | 750 | 2100 | 600 | 1300 | 800 | 3 |

| LDT1200 | >4200 | 2500 | 4200 | 4130 | 1200 | 750 | 2100 | 600 | 1300 | 960 | 3 |

| LDT1500 | >4600 | 2500 | 4400 | 4340 | 1200 | 750 | 2100 | 650 | 1300 | 1200 | 3 |

| LDT2000 | >4800 | 2500 | 4600 | 4620 | 1200 | 750 | 2100 | 650 | 1300 | 1600 | 3 |

| LDT2500 | >4500 | 2000 | 4200 | 4400 | 1400 | 750 | 2200 | 700 | 1350 | 2000 | 3 |

| LDT3000 | >4800 | 2000 | 4200 | 4650 | 1400 | 750 | 2200 | 700 | 1350 | 2400 | 3 |

Principle

The machine consists of the pillar, rotating chassis, lift fork, hydraulic system and control system. When working, It puts hopper filled with materials into the fork frame, then lifts operation lever, upgrades hopper to the height that feeding needs, twists the vertical pillar to connect with feeding device, then opens discharge butterfly valve, making the material move to the next process equipment.

Features

After the wide absorption of advanced domestic and foreign technology, and taking the specific conditions and requirements of this industry into consideration, our company develops this new equipment. It has proper structure, stable and reliable performance, and is easy to operate. Besides, it has high safety performance, equipped with multiple safety protection, such as rotating brake, and safety lock in the material discharging position.

Application

This machine is mainly used for lifting and feeding the Stainless steel turnover BIN .which can use together with tablet machine, mixer, granulator and other ancillary equipment. It is widely used in pharmaceutical, chemical, food and other industries.

![]()

![]()

![]()